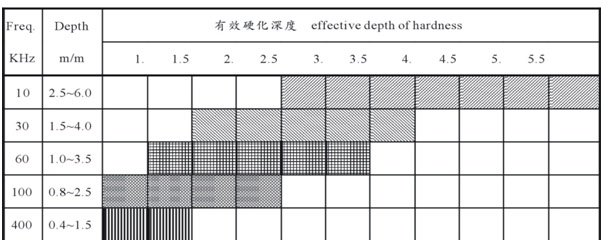

The high-frequency heat treatment device mainly uses induced current to heat the necessary surface parts of the workpiece, and performs necessary quenching, tempering and other heat treatment procedures to obtain surface characteristics with high surface hardness and good toughness in the center of the workpiece. The device mainly includes a high-frequency generator, heating coil and workpiece movement clamping mechanism. The heating efficiency of induction heating is very high. It can be heated to high temperature in a very short time and obtain an excellent hardened layer. The quenching heating depth and tempering treatment of this set of equipment are determined by the frequency of the induction coil current. The lower the frequency, the deeper the hardening depth. This is the skin effect.

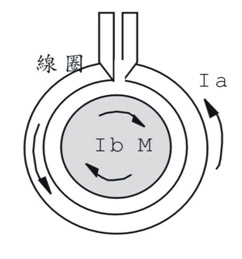

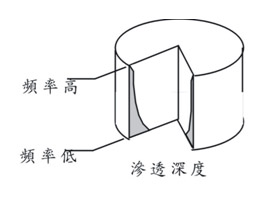

Eddy loss is used for heating (as shown in the left figure). When the high-frequency current Ia is passed through the coil, the metal body M must induce the current Ib. In addition, M is a locked circuit that causes the Ib current to be short-circuited, causing the temperature of the metal body M to rise rapidly. Rise, because the eddy current is caused by the induction of the metal body Ib by Ia, but not the entire metal has the current of Ib. It is different according to the frequency of the coil Ia. The higher the frequency, the more concentrated it is on the surface, and vice versa, the deeper it goes into the metal body. This is the skin effect (as shown in the picture on the right).